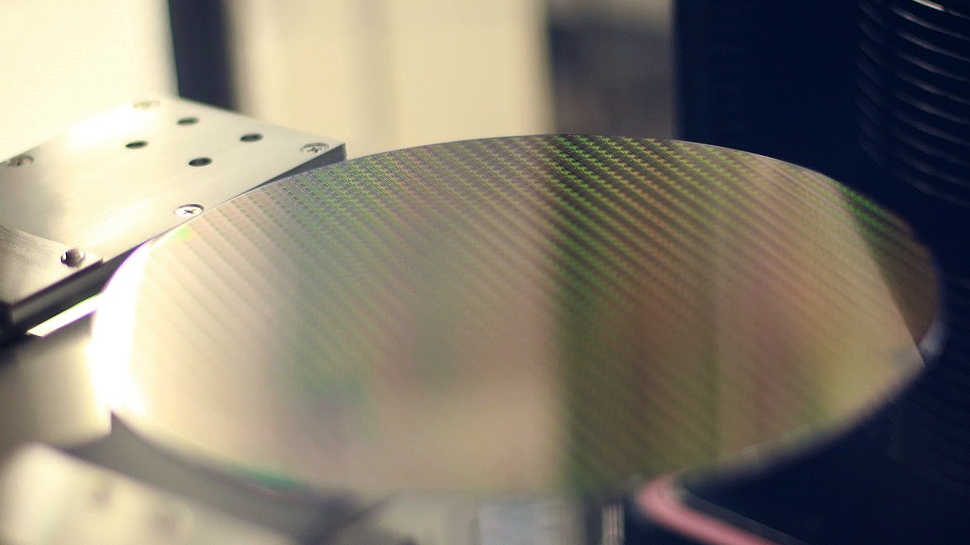

China chipmaker SMIC raises wafer prices by about 10% as memory demand tightens capacity

The adjustment comes as China’s largest foundry runs near full utilization and faces sustained demand from domestic customers building inventories of memory and logic chips.

(Image credit: SMIC)

Tom's Hardware Premium Roadmaps

China’s SMIC has raised wafer prices by roughly 10% across parts of its production portfolio, according to TrendForce, with memory-related products leading the increase. The adjustment, which is expected to take effect “shortly,” comes as China’s largest foundry runs near full utilization and faces sustained demand from domestic customers building inventories of memory and logic chips.

While SMIC has not publicly confirmed the change, the pricing shift is consistent with its recent financial disclosures showing utilization rates approaching the mid-90% range and improving margins after several quarters of pressure.

Memory products set the pace

By far the strongest driver behind the price increase is memory. SMIC does not compete directly with the largest DRAM and NAND vendors, but it plays an important role in China’s domestic memory ecosystem, supplying wafers and mature-node capacity to companies producing DRAM, specialty memory, and controller silicon.

After more than a year of oversupply, memory pricing began to firm earlier this year as manufacturers cut output and demand recovered from data centers, AI infrastructure, and consumer electronics. HBM, which is not yet in production in China, has absorbed a growing share of advanced capacity at leading-edge fabs, while conventional DRAM and NAND suppliers have been cautious about bringing idle lines back online. That imbalance has tightened supply across the value chain, including at foundries like SMIC that serve domestic memory programs.

From a timing perspective, raising prices now is more favorable for Chinese memory. The company’s most advanced processes remain constrained by export controls, but its mature and specialty nodes are heavily utilized. That has created a sweet spot for memory-related production because, by raising prices where demand is strongest, SMIC can drive up revenue per wafer without materially risking utilization. That’s a balance that has been difficult to achieve over the last few years, when the memory market was at odds with its current supply-and-demand dynamics.

Capacity pressure and geopolitics

SMIC’s decision to increase prices cannot be separated from the geopolitical environment shaping China’s semiconductor industry. Export restrictions on advanced manufacturing equipment have limited SMIC’s access to the most cutting-edge tools, but they have also accelerated domestic demand for locally produced chips at mature nodes. Chinese customers that once relied on overseas foundries have increasingly turned inward, pushing utilization higher at SMIC and peers such as Hua Hong.