Intel makes sharp reversal, is 'going big time into 14A,' says CEO Lip-Bu Tan — 'serve the customer well' remark hints at external client

Intel's CEO says he expects 'great momentum in terms of yields and IP' on the company's 14A process technology.

(Image credit: Getty / Justin Sullivan)

Although Intel's focus for this year's CES is to introduce its Core Ultra 3-series 'Panther Lake' processors and laptops, the company's chief executive, Lip-Bu Tan, still used the tradeshow to talk about 14A (1.4nm-class) process technology and reassure potential clients and investors that its development is proceeding well. The CEO's bullish statements marked a sharp reversal from his statements in July that the company would pause or discontinue the node if it didn't secure a customer.

"We are going big time into 14A," said Lip-Bu Tan in an Intel News video on X. "Stay tuned, we are going to see a lot of great momentum on the 14A in terms of yields [and] IP portfolio to serve the customer well."

Intel's 14A is expected to be production-ready in 2027, with early versions of process design kit (PDK) coming to external customers early this year. To that end, it is good to hear Intel’s upbeat comments about 14A. Also, Tan’s phrasing ‘the customer’ (plural) indicates that Intel has more than one client for 14A, implying that Intel Foundry will produce 14A chips for Intel Products and at least one more buyer.

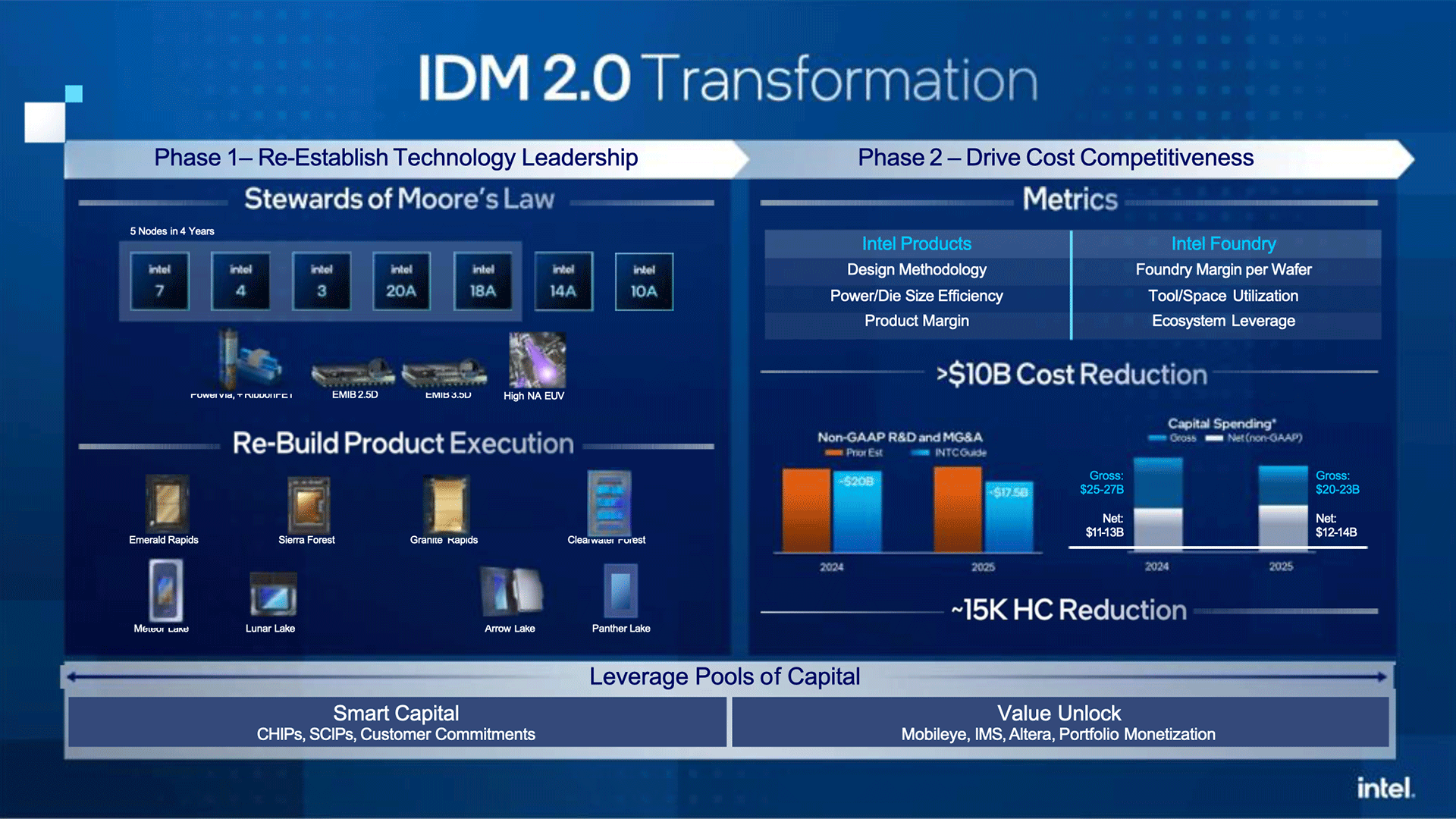

(Image credit: Intel)

It goes without saying that Intel's 18A fabrication technology — which is used to make the compute tile of Panther Lake processors — is an important manufacturing process for Intel in the sense that it introduces gate-all-around (GAA) RibbonFET transistors and PowerVia backside power delivery network (BSPDN). However, 14A is by all means no less important because it builds on top of what the company will learn 18A. The 14A production node will introduce Intel's 2nd Generation RibbonFET GAA transistors; 2nd Gen BSPDN called PowerDirect that will connect power directly to source and drain of transistors, enabling better power delivery (e.g., reducing transient voltage droop or clock stretching) and refined power controls; and Turbo Cells that optimize critical timing paths using high-drive, double-height cells within dense standard cell libraries, which boost speed without major area or power compromises.

Yet, there is another aspect of Intel's 14A manufacturing process that is particularly important for the chipmaker: its usage by external customers. With 18A, the company has not managed to land a single major external client that demands decent volumes. While 18A will be used by Intel itself as well as by and the U.S. Department of Defense, only Intel will consume significant volumes. For 14A, Intel hopes to land at least one more external customer with substantial volume requirements, as this will ensure that Intel will recoup its investments in the development of such an advanced node.